Hard Chrome Plated Rod Introduction – by Chrome plated Shafting Manufacturer

Hard Chrome plated rod is known as chrome plated shafting also, they are the same product. This product is usually manufactured from cold rolled or hot rolled carbon steel round rod, by using high precision centerless grinding and polishing methods, and then chrome plated to a certain plating thickness such as min. 20 microns (0.0008″), min. 25 microns (0.001″), min. 50μm (0.002″) and so on.

Guangxi is a leading China chrome plated rod manufacturer factory and supplier. Our factory produces and supplies chrome plated rods with full range of steel grades and dimensions.

As the chrome plated rod is usually used as hydraulic cylinder shafts, pneumatic cylinder shafts and other machine shafts, so they are known as Hard Chrome Plated Shafts also.

TABLE OF CONTENT

Chrome plated rods: Product description

Product Materials

- SAE 1045: SAE 1045 hard chrome plated rod

- CK45: CK45 chrome plated rod

- C45: C45 chrome plated rod

- C45E: C45E hard chrome rod

- SAE 4140: 4140 chrome plated rods

- 27SiMn: 27SiMn chrome plated rod

Product Sizes

Our hard chrome plated shafting is available with sizes as below.

Metric Size: Diameter min. 10 mm, and max. 900 mm;

Imperial Size: diameter 3/8″ to 36″

Length: fixed length 100mm to 14000 mm, random length available.

Tolerance: f7, f8, g6, and so on.

Chrome plated rod Heat treatment

Chrome plated rods can be supplied with heat treatment condition as below.

- Induction hardened, high frequency hardening, etc.

- Q&T: Quenching and Tempering heat treatment

Chrome plated shafting Surface Condition

The surface roughness of the chrome plated shafting comes in two series which are Max Ra 0.2 μm and max Ra 0.4μm.

Chrome plating Thickness

The chrome layer thickness of our chrome plated rod is Available in Min. 20 microns, 25 microns, 30 microns, … 60 microns.

Main types of Chrome plated rod

CK45 chrome plated rod

Product Name: CK45 chrome plated rod; CK45 chrome plated bar; CK45 chrome plated shafting.

Origin (factory located): China, Wuxi

Brand Name: GUANGXI

Size Range

- Diameter: 6mm to 850 mm

- Length: max 18 meters

- Imperial sizes and metric sizes both are available

[bg_collapse view=”button-blue” icon=”zoom” color=”#ffffff” expand_text=”Show More” collapse_text=”Show Less” ]Heat Treatment type:

- Q&T (Quenched+Tempered)

- Induction hardned (high frequency induction ect)

- Q&T + Induction hardened

- No heat treated

Precision tolerances and surface finish.

Твердость: Rc 60-72

Thcikness of chrome plated layer:

- Min. 20 microns

- Min 25 microns (0.001″)

- Min 30 microns

- Min 50 microns (0.002″)

- Customized

[/bg_collapse]

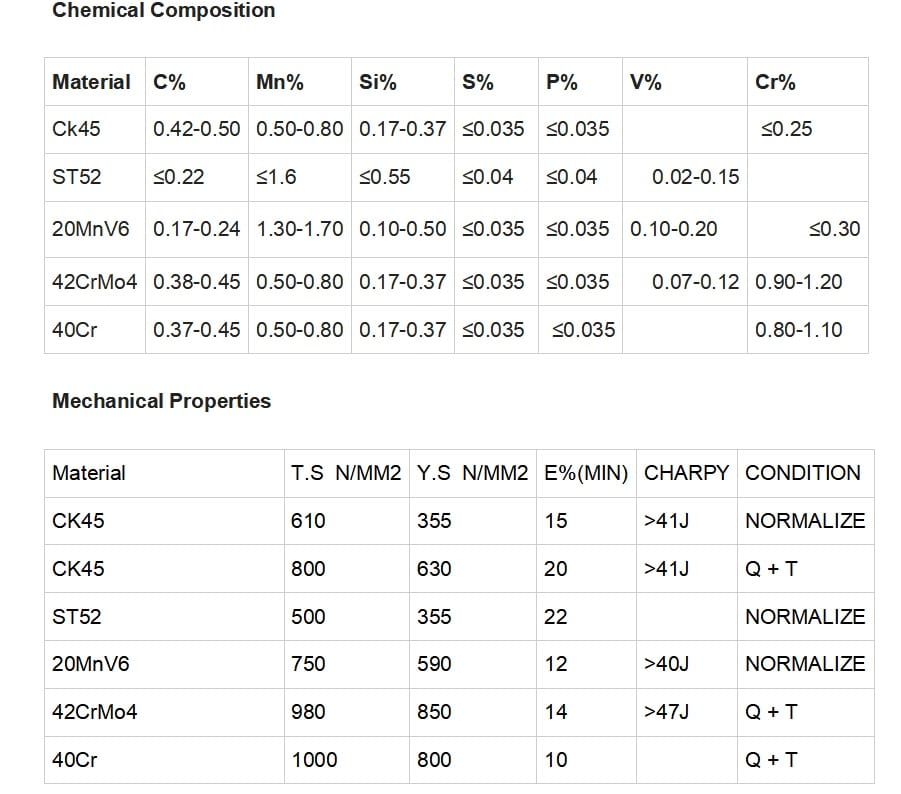

Steel grade CK45 is equivalent to SAE standard grade of SAE 1045, so this product is also known as 1045 chrome plated rod or 1045 Chrome rod. Here below is the chemical composition and mechanical properties of CK45.

| Марка стали | Химический состав % | ||||

| Углерод | Мн . | Si | P | S | |

| CK45 (C45) | 0.42-0.50 | 0.50-0.80 | 0,40 Макс. | 0,035 Макс. | 0,035 Макс. |

| Марка стали | Механические свойства | |||

| Предел текучести | Прочность на растяжение | Удлинение | Твердость | |

| СК 45 | 75K psi / 517 Mpa | 85K psi / 585Mpa | 10% | Рк 60-72 |

- Толщина твердого Хромированного покрытия:

Our CK45 chrome rod normally is with chrome plated thickness of Min. 20Microns (0.0008″) or Min. 25 Microns (0.001″) ;

And other hard chrome plated thickness available upon customer’s requirements, the max. chrome thickness is 50microns.

Our factory’s chrome rods can pass the salt spray tested to at least 48 hours in accordance with ASTM B-117. - Шероховатость поверхности:

The surface roughness of our factory’s CK45 hard chrome plated rod is around Ra0.2μm(8 Ra), max. Ra0.4μm (16 Ra). - Hardness:

Hardness of hard chrome plated layer is Min. HV900.

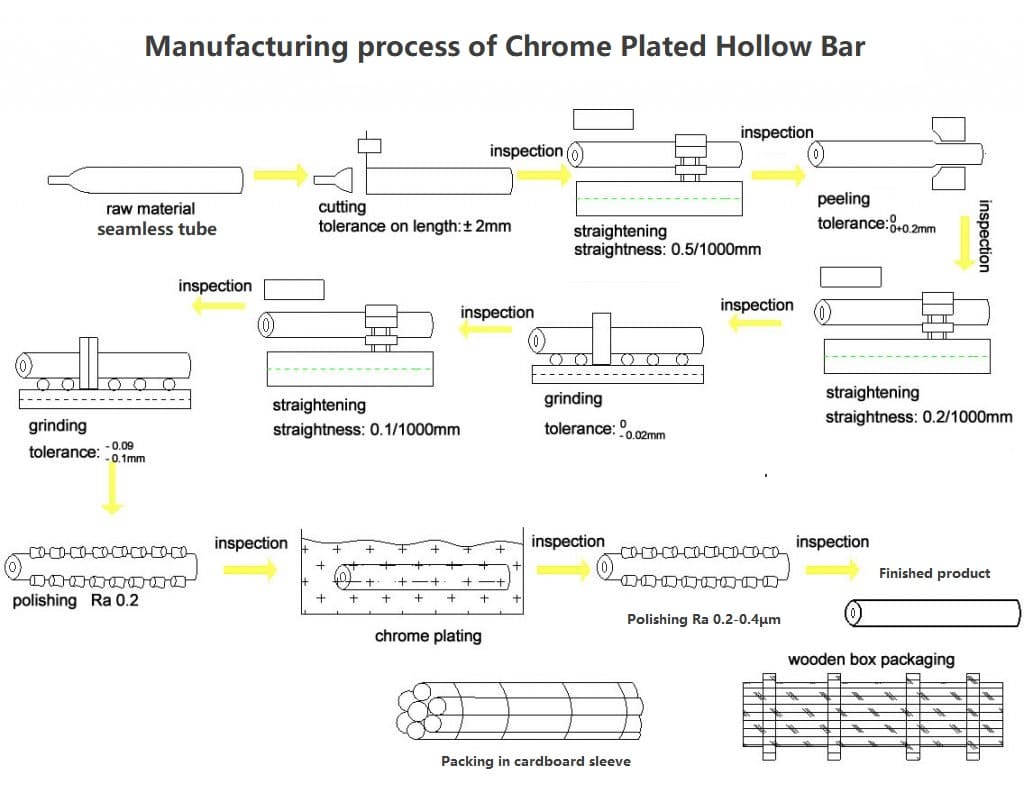

Here below is the main process showing how hard chrome plated shaft is manufactured.

1045 Chrome Plated Rod

Product Name: 1045 chrome plated rod; 1045 chrome plated bar; 1045 chrome plated shafting

Material: SAE1045

[bg_collapse view=”button-blue” icon=”zoom” color=”#ffffff” expand_text=”Show More” collapse_text=”Show Less” ]

Heat Treatment:

- Q+T(Quenched+Tempered)

- Induction Hardened

- No heat treated

Diameter: Φ 6-800mm

Length: max.20 meters

Chrome plated layer thickness: min 20μm, 25μm, 30μm, 50 Microns or customized upon request.

Straightness: <= 0.5/1000

Surface finish: Max Ra 0.4μm (16 RA)

Diameter tolerance: ISO f7/f8/f9/h8/h9 or as request

Protection: Diameter Anti-rust oiled, protected with hard cardboard sleeve.

Packing: Wooden case

WHAT IS THE ADVANTAGES OF OUR 1045 CHROME PLATED ROD?

- Carbon steel balances durability, hardness, and wear resistance using formability, weldability, and durability;

- Chrome plating provides corrosion resistance along with an Extremely reflective look

- High precision tolerances, which ensures when used to make hydraulic piston rod, it can fit the cylinder precisely.

- Good Hardness: the surface hardness attaining HV850 minimal and upward, which not only help improve wear resistance but also help extend the life span of these chrome plated rods, thereby helping the consumer save the cost.

[/bg_collapse]

Below is the chemical compostion & mechanical properties of Steel 1045 chrome rods.

| Марка стали | Химический состав % | ||||

| Углерод | Мн . | Si | P | S | |

| SAE 1045 | 0.43-0.50 | 0.60-0.90 | – | 0,040 Макс. | 0,050 Макс. |

| Марка стали | Механические свойства | ||||

| Предел текучести | Прочность на растяжение | Удлинение | Твердость | ||

| SAE 1045 | 75000 фунтов на квадратный дюйм / 517 Мпа | 85000 фунтов на квадратный дюйм / 585 МПа | 10% | Рк 60-72 | |

Our 1045 chrome shafts can be supplied with tolerance of g6, f7, f8 and f9 on customers request. Here below is the tolerance chart.

| Допуски для хромированных валов (ISO 286-2) | |||||||||||

| закончился | вплоть до | Верхний и Нижний пределы в микрометрах (0,001 мм) | |||||||||

| d9 | e8 | f7 | g6 | h5 | h6 | h7 | h8 | h9 | h11 | ||

| – | 3 | -20 | -14 | -6 | -2 | 0 | 0 | 0 | 0 | 0 | 0 |

| -45 | -28 | -16 | -8 | -4 | -6 | -10 | -14 | -25 | -60 | ||

| 3 | 6 | -30 | -20 | -10 | -4 | 0 | 0 | 0 | 0 | 0 | 0 |

| -60 | -38 | -22 | -12 | -5 | -8 | -12 | -18 | -30 | -75 | ||

| 6 | 10 | -40 | -25 | -13 | -5 | 0 | 0 | 0 | 0 | 0 | 0 |

| -76 | -47 | -28 | -14 | -6 | -9 | -15 | -22 | -36 | -90 | ||

| 10 | 18 | -50 | -32 | -16 | -6 | 0 | 0 | 0 | 0 | 0 | 0 |

| -93 | -59 | -34 | -17 | -8 | -11 | -18 | -27 | -43 | -110 | ||

| 18 | 30 | -65 | -40 | -20 | -7 | 0 | 0 | 0 | 0 | 0 | 0 |

| -117 | -73 | -41 | -20 | -9 | -13 | -21 | -33 | -52 | -130 | ||

| 30 | 50 | -80 | -50 | -25 | -9 | 0 | 0 | 0 | 0 | 0 | 0 |

| -142 | -89 | -50 | -25 | -11 | -16 | -25 | -39 | -62 | -160 | ||

| 50 | 65 | -100 | -60 | -30 | -10 | 0 | 0 | 0 | 0 | 0 | 0 |

| -174 | -106 | -60 | -29 | -13 | -19 | -30 | -46 | -74 | -190 | ||

| 65 | 80 | -100 | -60 | -30 | -10 | 0 | 0 | 0 | 0 | 0 | 0 |

| -174 | -106 | -60 | -29 | -13 | -19 | -30 | -46 | -74 | -190 | ||

| 80 | 100 | -120 | -72 | -36 | -12 | 0 | 0 | 0 | 0 | 0 | 0 |

| -207 | -126 | -71 | -34 | -15 | -22 | -35 | -54 | -87 | -220 | ||

| 100 | 120 | -120 | -72 | -36 | -12 | 0 | 0 | 0 | 0 | 0 | 0 |

| -207 | -126 | -71 | -34 | -15 | -22 | -35 | -54 | -87 | -220 | ||

| 120 | 140 | -145 | -85 | -43 | -14 | 0 | 0 | 0 | 0 | 0 | 0 |

| -245 | -148 | -83 | -39 | -18 | -25 | -40 | -63 | -100 | -250 | ||

| 140 | 160 | -145 | -85 | -43 | -14 | 0 | 0 | 0 | 0 | 0 | 0 |

| -245 | -148 | -83 | -39 | -18 | -25 | -40 | -63 | -100 | -250 | ||

| 160 | 180 | -145 | -85 | -43 | -14 | 0 | 0 | 0 | 0 | 0 | 0 |

| -245 | -148 | -83 | -39 | -18 | -25 | -40 | -63 | -100 | -250 | ||

| 180 | 200 | -170 | -100 | -50 | -15 | 0 | 0 | 0 | 0 | 0 | 0 |

| -285 | -172 | -96 | -44 | -20 | -29 | -46 | -72 | -115 | -290 | ||

| 200 | 225 | -170 | -100 | -50 | -15 | 0 | 0 | 0 | 0 | 0 | 0 |

| -285 | -172 | -96 | -44 | -20 | -29 | -46 | -72 | -115 | -290 | ||

| 225 | 250 | -170 | -100 | -50 | -15 | 0 | 0 | 0 | 0 | 0 | 0 |

| -285 | -172 | -96 | -44 | -20 | -29 | -46 | -72 | -115 | -290 | ||

| 250 | 280 | -190 | -110 | -56 | -17 | 0 | 0 | 0 | 0 | 0 | 0 |

| -320 | -191 | -108 | -49 | -23 | -32 | -52 | -81 | -130 | -320 | ||

| 280 | 315 | -190 | -110 | -56 | -17 | 0 | 0 | 0 | 0 | 0 | 0 |

| -320 | -191 | -108 | -49 | -23 | -32 | -52 | -81 | -130 | -320 | ||

| 315 | 355 | -210 | -125 | -62 | -18 | 0 | 0 | 0 | 0 | 0 | 0 |

| -350 | -214 | -119 | -54 | -25 | -36 | -57 | -89 | -140 | -360 | ||

| 355 | 400 | -210 | -125 | -62 | -18 | 0 | 0 | 0 | 0 | 0 | 0 |

| -350 | -214 | -119 | -54 | -25 | -36 | -57 | -89 | -140 | -360 | ||

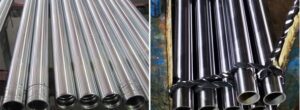

Our factory’s chrome plated shafts are oiled with anti-rust oil on the outer diameter surface, then each chromed shaft is protected with a cardboard sleeve (paper tube), and then packed in wooden cases. Please refer to below photos.

Induction hardened chrome plated rod

Induction hardening of piston rods in hydraulic cylinders is performed in order to increase the resistance to damage from external impact in applications where there is risk for them.

As the first level chrome plated rod manufacturer, our factory has been manufacturing & supplying Induction Hardened Chrome Plated Rods for more than 25 years, our hard chrome plated rod and Induction Hardened Chrome Plated shafts are widely used in hydraulic cylinders and pneumatic cylinders.

[bg_collapse view=”button-blue” icon=”zoom” color=”#ffffff” expand_text=”Show More” collapse_text=”Show Less” ]

The Induction hardened chrome plated rod results in a superior impact resistant bar ideal for high quality piston rods capable of handling tough environments.

- Steel grades: AISI 1045 / 1050, 4140, CK45, C45, 42CrMo, 20MnV6, 27SiMn

- Typically meets ASTM A108, A311 class B

- Size Range:

- Metric size diameter 6 mm to 800mm, imperail sizes available.

- Induction hardened chrome rod length: Max. 18 meters.

- Hardness of chrome plating HRc 60-72

- Surface hardness of HRc 50 minimum

- Minimum hardness case depth at 1mm

- Hard chrome plated thickness per side: minimum 15 microns /20 microns/ 25 microns, 30microns, 50 μm

- Surface finish of roughness Max Ra 0.4μm, (16 Ra maximum)

- Offered in minimum yield strengths of 75k and 100k

- Custom made diameters and chrome thickness available upon request.

- Heat treatment:

- Induction Hardened Rod (HRC 55-62)

- Q&T(Quenching and tempering) Induction Hardened Rod (HRC 60-65)

[/bg_collapse]

Different from the normal chrome plated rods, the induction hardened chrome plated rods are heat treated by induction hardening.

Induction hardened is a type of heat treatment process, for which a metal part is heated to a certain temperature by induction heating and then quenched.

Here below are the material specifcaitons of the induction hardened chrome plated shafting.

| Марка стали | Химический состав % | ||||

| Углерод | Мн . | Si | P | S | |

| SAE 1045 | 0.43-0.50 | 0.60-0.90 | – | 0,040 Макс. | 0,050 Макс. |

| СК 45 | 0.42-0.50 | 0.50-0.80 | 0,40 Макс. | 0,035 Макс. | 0,035 Макс. |

And below is the chemical composition of 4140 chrome plated rod for shafts.

| SAE 4140 | C% | Si% | Мн .% | P% | S% | Cr% | Мо% |

| Мин | 0.36 | 0.1 | 0.65 | 0.75 | 0.15 | ||

| Макс | 0.44 | 0.4 | 1.1 | 0.04 | 0.04 | 1.2 | 0.35 |

Механические свойства

| Марка стали | Механические свойства | |||

| Предел текучести | Прочность на растяжение | Удлинение | Твердость | |

| SAE 1045 | 75000 фунтов на квадратный дюйм / 517 Мпа | 85000 фунтов на квадратный дюйм / 585 МПа | 10% | Рк 60-72 |

| СК 45 | 75000 фунтов на квадратный дюйм / 517 Мпа | 85000 фунтов на квадратный дюйм / 585 МПа | 10% | Рк 60-72 |

With special heat treatment, the yield strength of our induction hardened chrome plated rod can be min. 100K psi (690 Mpa).

For induction hardened chrome plated rods require high strength, we can supply with material 4140. Here below are the mechanical properties of SAE 4140.

| 4140 | Предел текучести | Прочность на растяжение | Удлинение | Твердость HB |

| Мин | 800 Мпа /115 К фунтов на квадратный дюйм | 900 Мпа /130 К фунтов на квадратный дюйм | 20% | 270 НВ |

Induction hardened chrome plated rods have various applications due to their strength, durability, and resistance to corrosion. Some common applications include:

- Hydraulic cylinders: Induction hardened chrome plated rods are widely used in hydraulic cylinders as they can withstand high pressures and offer excellent corrosion resistance. The hard outer surface also reduces wear and tear on the cylinder, increasing its lifespan.

- Linear motion systems: These rods are used in linear motion systems such as linear guides, linear actuators, and linear bearings. The hard outer surface helps to reduce friction and wear, allowing for smoother and more precise movement.

- Pneumatic cylinders: Induction hardened chrome plated rods are also used in pneumatic cylinders, which operate similarly to hydraulic cylinders but use compressed air instead of hydraulic fluid. The rods offer similar benefits in terms of durability and resistance to corrosion.

- Printing and packaging machinery: The rods are used in printing and packaging machinery, which require high precision and durability. They are often used in parts such as rollers, guides, and bearings.

- Construction machinery: Induction hardened chrome plated rods are used in various construction machinery such as cranes, excavators, and bulldozers. Their strength and durability make them ideal for heavy-duty applications.

[bg_collapse view=”button-blue” icon=”zoom” color=”#ffffff” expand_text=”Show More” collapse_text=”Show Less” ]

Material: SAE4140, AISI 4140, 4140; 42CRMO4/42CrMo, SCM440

Heat treatments:

- Q+T(Quenched+Tempered)

- Induction Hardened (high frequency hardening, etc)

Diameter: Φ 6-800mm

Длина: max 21 meters

Chrome plated layer thickness: min. 20 microns, 25 microns, min.30 mcirons, min.50 Microns or customized thickness.

Straightness: <= 0.5/1000

Surface Roughness: Max. 0.4μm

Hardness of the chrome layer: 900 HV (min) – 1150 HV

Diameter tolerance: ISO f7/f8/f9/h8/h9 or as request

Упаковка: Anti-rust oiled outside, protect with hard cardboard tube, and then put into wooden case.

Delivery Condition:

- Hard Chrome Plated Rod

- Quenched & Tempered (Q+T) hard chrome plated rod

- Induction Hardened chrome plated rod

- Q+T Induction Hardened chromed rod

[/bg_collapse]

Below is the chemical composition of 4140 chrome plated shafts.

| SAE 4140 | C% | Si% | Мн .% | P% | S% | Cr% | Мо% |

| Мин | 0.36 | 0.1 | 0.65 | 0.75 | 0.15 | ||

| Макс | 0.44 | 0.4 | 1.1 | 0.04 | 0.04 | 1.2 | 0.35 |

Здесь ниже приведены механические свойства SAE 4140.

| 4140 | Предел текучести | Прочность на растяжение | Удлинение | Твердость HB |

| Мин | 800 Мпа /115 К фунтов на квадратный дюйм | 900 Мпа /130 К фунтов на квадратный дюйм | 20% | 270 НВ |

HERE BELOW IS THE APPLICATION LIST OF THE CHROME RODS:

- Hydraulic cylinders (chrome plated piston rods)

- Pneumatic cylinders / air cylinders (hydraulic cylinder piston rods)

- Guide rods for plastic manufacturing machine and hydraulic machinery

- Rollers for machines, such as packing machine rollers, printing machine rollers

- Shaft for machinery, such as Textile machinery center axle, Transport machinery center axle, etc.

- Ejector rods for injection molding machines

- Vibration absorbers and pistons for some industrial machinery.

1. Extensive production experience: more than 25 years manufacturing experience for 4140 honed tube and SAE 4140 chrome plated rod, in Australia, Thailand, Brazil, India, Iran, Indonesia, South Africa and other countries have long-term buyers.

2. Advanced production equipment: cold drawing machine, honing machine, skiving & roller burnishing machine, straightening machine, polishing machine, heat treatment furnace, grinding machine, etc. We have professional technicians do regular scheduled maintenance on these machines to guarantee them work well.

3. High quality raw material: our raw material of SAE 4140 steel mainly from some famous steel mills, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest 4140 steel manufacturer in China.

4. High precision: The chrome Plated Rod, chrome layer 10 micron to 100 micron, with strict tolerance ISO268 / f7.

5. Strict quality control: we have professional in-house QC to inspect all chrome plated shafting. We will do Chemical Composition Test, Mechanical Property Test, Dimension Inspect, Roughness Test, Chrome Layer Test and other tests in need before delivery.

6. Safe packing: an-rust oil on rods before delivery. Each chrome plated shafting will be packed in a single cardboard tube. Then be packed with seaworthy package or in wooden case.

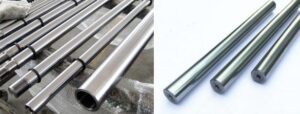

Here below is a photo of our 4140 hard chrome plated shafts/rods.

Below is the product descriptions of chrome plated hollow rods:

[bg_collapse view=”button-blue” icon=”zoom” color=”#ffffff” expand_text=”Show More” collapse_text=”Show Less” ]

Material: ST52, E355, CK45, 4140, 42CrMo, 27SiMn, SAE1045;

Heat treatment Type:

- BKS: for ST 52, E355

- +SR: for material St52, E355

- Q+T (Quenching and tempering ) for CK45, SAE 1045, 4140, 42CrMo

- Hard: +C /EN10305-1; BK(DIN2391)

OD Size : 20mm – 1600mm

Длина: max. 21 meters

Chrome layer: min 20/25/30/50 Microns or customized

Type: Seamless, Hot Rolled, Cold Rolled, Cold Drawn

Straightness: ≤ 0.5/1000

Roughness: OD Ra 0.2μm, max. 0.4μm

Tolerance EXT: DIN2391, EN10305, ASTM A519

Diameter tolerance: ISO f7/f8/f9/h8/h9 or as request

Protection: Anti-rust oil on inside and outside surface.

Упаковка: Hard cardboard tube protection and then wrapped with rope or in wooden case.

CHEMICAL COMPOSITION & MECHANICAL PROPERTIES OF CHROME PLATED HOLLOW ROD

[/bg_collapse]

Why Choose Us?

Customer trust us and choose us because of our below adavantages.

WHAT IS THE ADVANTAGES OF OUR CHROME PLATED HOLLOW ROD?

Our Product advantages:

- Carbon steel balances durability, hardness, and wear resistance using formability, weldability, and durability;

- Chrome plating provides corrosion resistance along with an Extremely reflective look

- High precision tolerances, which ensures when used to make hydraulic piston rod, it can fit the cylinder precisely.

- Good Hardness: the surface hardness attaining HV850 minimal and upward, which not only help improve wear resistance but also help extend the life span of these chrome plated rods, thereby helping the consumer save the cost.

Company Advantages:

1.Extensive production experience: more than 20 years manufacturing experience for honed tube and chrome plated rod, in Australia, Thailand, Brazil, India, Iran, Indonesia, South Africa and other countries have long-term buyers.

2.Advanced production equipment: cold drawing machine, honing machine, skiving & roller burnishing machine, straightening machine, polishing machine, heat treatment furnace, grinding machine, etc. We have professional technicians do regular scheduled maintenance on these machines to guarantee them work well.

3.High quality raw material: our raw material mainly from some famous steel mills, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest raw material manufacturer in China.

4.High precision: Chrome Plated Rod, chrome layer thickness from 10 micron to 100 micron, strict diameter tolerance ISO f7.

5.Strict quality control: we have professional in-house QC to inspect all products. We will do Chemical Composition Test, Mechanical Property Test, Dimension Inspect, Roughness Test, Chrome Layer Test and other tests in need before delivery.

6.Safe packing: an-rust oil on rods before delivery. Each single chrome plated hollow rod will be packed separately in a cardboard tube. Then be packed with seaworthy package or in wooden case.

Hard Chrome plated hollow rods are usually manufactured from cold drawn seamless tubes with grinding and polishing on the outer diameter, and then chrome plated to a certain thickness. Sometimes, the mother material of the chromed hollow rod is hot rolled seamless tubes. Here below is the main process of how is the hard chrome plated hollow rods are manufactured.

WE ALSO MANUFACTURE BELOW PRODUCTS:

- Hard Chrome Plated Bar

- Hard Chrome Plated Rods

- Chrome Plated Hollow bar

- Hard Chrome Plated Hollow Rods

- Induction Hardened Chrome Bar

- Hard Chrome Plated Piston Rod

- Hard Chrome Shaft

- Hard Chrome Plated Shaft

- Honed Tube

- Ready To Honed Tube (Cold Drawn Seamless Tube)

- Hydraulic Cylinder Barrel

- Трубки гидравлического цилиндра

Our factory can supply highest quality hard chrome plated bars and chrome rods to customers all over the world. If you are interested in our hard chrome piston rod, chrome rod, chrome plated bars, please contact us by email to [email protected]

TEL: +861775-285-6381