CK45 Chrome Plated Bar| CK45 Chrome Rod | CK45 Chrome Bar Overview

As a reputable and leading supplier and manufacturer of Hard Chrome Plated Bars, our factory produces and supplies top-quality CK45 Chrome Plated Rods ranging in diameter from 6mm to 900mm.

What is CK45 chrome plated rod?

CK45 chrome plated rod is also called CK45 chrome rod or CK45 chrome bar for short sometimes. This product is the hard chrome plated bar made of steel grade CK45, it is widely used as the material of producing hydraulic cylinder rod, thus some people also call it CK45 hydraulic piston rod or CK45 hydraulic cylinder rod.

The CK45 chrome plated bar is a medium-tensile carbon steel made from CK45 material and supplied in a cold drawn or turned, precision ground, polished, chrome plated, and final polished condition. With a tensile strength of 670-800 Mpa and a yield strength of approximately 520 Mpa (75Ksi), CK45 steel is a strong and durable material.

CK45 is equivalent to the SAE 1045 standard, so this product is also referred to as the 1045 chrome plated rod or 1045 Chrome Bar. The chemical composition and mechanical properties of CK45 are provided below.

| Steel Grade | Chemical Composition % | ||||

| Carbon | Mn | Si | P | S | |

| CK45 (C45) | 0.42-0.50 | 0.50-0.80 | 0.40 Max | 0.035 Max | 0.035 Max |

| Steel Grade | Mechanical Properties | |||

| Yield Strength | Tensile Strength | Elongation | Hardness | |

| CK 45 | 75K psi / 517 Mpa | 85K psi / 585Mpa | 10% | Rc 60-72 |

Product Details of CK45 Hard Chrome Plated Rod

As the reputable CK45 chrome plated bar supplier, our factory produces CK45 chrome rods with details as below.

CK45 Chrome Bar dimensions

- Production range:

Our factory supplies CK45 chrome bar with a wide range of metric and inch sizes as below.- Round Diameter 10 mm to 900 mm;

- Imperial inch size chrome rod available from 3/8″ to 36″

- Length:

Our factory provides CK45 chrome plated rods for hydraulic cylinders, also known as CK45 hydraulic piston rods, with the option for either random or fixed lengths (cut to length) as per the customer’s request. The maximum length available can be up to 15 meters.

Diameter tolerance of CK45 chrome rods

Our factory’s CK45 chrome plated rods can be supplied with tolerance of ISO g6, f7, f8 and f9 on customers’ request. Here below is the standard tolerance table.

| Tolerances for Chrome Rods (ISO 286-2) | |||||||||||

| over | up to | Upper and Lower limits in micrometer (0.001 mm) | |||||||||

| d9 | e8 | f7 | g6 | h5 | h6 | h7 | h8 | h9 | h11 | ||

| – | 3 | -20 | -14 | -6 | -2 | 0 | 0 | 0 | 0 | 0 | 0 |

| -45 | -28 | -16 | -8 | -4 | -6 | -10 | -14 | -25 | -60 | ||

| 3 | 6 | -30 | -20 | -10 | -4 | 0 | 0 | 0 | 0 | 0 | 0 |

| -60 | -38 | -22 | -12 | -5 | -8 | -12 | -18 | -30 | -75 | ||

| 6 | 10 | -40 | -25 | -13 | -5 | 0 | 0 | 0 | 0 | 0 | 0 |

| -76 | -47 | -28 | -14 | -6 | -9 | -15 | -22 | -36 | -90 | ||

| 10 | 18 | -50 | -32 | -16 | -6 | 0 | 0 | 0 | 0 | 0 | 0 |

| -93 | -59 | -34 | -17 | -8 | -11 | -18 | -27 | -43 | -110 | ||

| 18 | 30 | -65 | -40 | -20 | -7 | 0 | 0 | 0 | 0 | 0 | 0 |

| -117 | -73 | -41 | -20 | -9 | -13 | -21 | -33 | -52 | -130 | ||

| 30 | 50 | -80 | -50 | -25 | -9 | 0 | 0 | 0 | 0 | 0 | 0 |

| -142 | -89 | -50 | -25 | -11 | -16 | -25 | -39 | -62 | -160 | ||

| 50 | 65 | -100 | -60 | -30 | -10 | 0 | 0 | 0 | 0 | 0 | 0 |

| -174 | -106 | -60 | -29 | -13 | -19 | -30 | -46 | -74 | -190 | ||

| 65 | 80 | -100 | -60 | -30 | -10 | 0 | 0 | 0 | 0 | 0 | 0 |

| -174 | -106 | -60 | -29 | -13 | -19 | -30 | -46 | -74 | -190 | ||

| 80 | 100 | -120 | -72 | -36 | -12 | 0 | 0 | 0 | 0 | 0 | 0 |

| -207 | -126 | -71 | -34 | -15 | -22 | -35 | -54 | -87 | -220 | ||

| 100 | 120 | -120 | -72 | -36 | -12 | 0 | 0 | 0 | 0 | 0 | 0 |

| -207 | -126 | -71 | -34 | -15 | -22 | -35 | -54 | -87 | -220 | ||

| 120 | 140 | -145 | -85 | -43 | -14 | 0 | 0 | 0 | 0 | 0 | 0 |

| -245 | -148 | -83 | -39 | -18 | -25 | -40 | -63 | -100 | -250 | ||

| 140 | 160 | -145 | -85 | -43 | -14 | 0 | 0 | 0 | 0 | 0 | 0 |

| -245 | -148 | -83 | -39 | -18 | -25 | -40 | -63 | -100 | -250 | ||

| 160 | 180 | -145 | -85 | -43 | -14 | 0 | 0 | 0 | 0 | 0 | 0 |

| -245 | -148 | -83 | -39 | -18 | -25 | -40 | -63 | -100 | -250 | ||

| 180 | 200 | -170 | -100 | -50 | -15 | 0 | 0 | 0 | 0 | 0 | 0 |

| -285 | -172 | -96 | -44 | -20 | -29 | -46 | -72 | -115 | -290 | ||

| 200 | 225 | -170 | -100 | -50 | -15 | 0 | 0 | 0 | 0 | 0 | 0 |

| -285 | -172 | -96 | -44 | -20 | -29 | -46 | -72 | -115 | -290 | ||

| 225 | 250 | -170 | -100 | -50 | -15 | 0 | 0 | 0 | 0 | 0 | 0 |

| -285 | -172 | -96 | -44 | -20 | -29 | -46 | -72 | -115 | -290 | ||

| 250 | 280 | -190 | -110 | -56 | -17 | 0 | 0 | 0 | 0 | 0 | 0 |

| -320 | -191 | -108 | -49 | -23 | -32 | -52 | -81 | -130 | -320 | ||

| 280 | 315 | -190 | -110 | -56 | -17 | 0 | 0 | 0 | 0 | 0 | 0 |

| -320 | -191 | -108 | -49 | -23 | -32 | -52 | -81 | -130 | -320 | ||

| 315 | 355 | -210 | -125 | -62 | -18 | 0 | 0 | 0 | 0 | 0 | 0 |

| -350 | -214 | -119 | -54 | -25 | -36 | -57 | -89 | -140 | -360 | ||

| 355 | 400 | -210 | -125 | -62 | -18 | 0 | 0 | 0 | 0 | 0 | 0 |

| -350 | -214 | -119 | -54 | -25 | -36 | -57 | -89 | -140 | -360 | ||

The steel rods are grinded, polished and chrome plated, the surface quality is like below.

- Hard Chrome Plated Thickness:

Our CK45 chrome plated rod typically has a minimum chrome plating thickness of 20 microns (0.0008 inches) or 25 microns (0.001 inches). The maximum chrome thickness can be up to 50 microns, with other thickness options available based on customer requirements. Our factory’s chrome rods can withstand salt spray testing for a minimum of 48 hours in compliance with ASTM B-117 standards. - Surface roughness:

The surface roughness of our factory’s CK45 hard chrome plated bar is around Ra0.2μm(8 Ra), max. Ra0.4μm (16 Ra).

- Good hardness: Hard chrome plated surface hardness of Min. HV 900

- Super smooth surface finish with excellent wear and corrosion resistance

- High precision dimension tolerance

- The base material of the CK45 chrome plated bar offers robust strength and resilience to impact, as well as displaying good machinability and sufficient weldability properties.

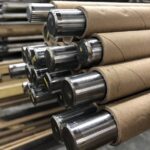

Our factory, a professional supplier of CK45 chrome plated rods, ensures safe transportation by providing reliable packaging methods. Our standard packaging consists of a cardboard and rope or a wooden case. To preserve the smooth exterior diameter of the CK45 chrome bars, each bar is placed in a cardboard (paper tube) and then wrapped with ropes to form a bundle. Alternatively, the bars with their cardboard packaging can be placed in wooden boxes for added protection.

Why choose our CK45 chrome rod?

Here below are the main advantages of our chrome bars and services.

- Almost 30 years’ production experience for chrome plated steel rods;

- Our factory is equipped with advanced manufacturing machines and facilities, including 10 cold drawing machines, 3 straightening machines, 20 polishing machines, 2 heat treatment furnaces, and 15 grinding machines, to name a few. These machines are regularly maintained by our skilled engineers to ensure their optimal functioning.

- Quality raw materials: our raw materials for chrome plated rods are mainly from the famous China steel manufacturers, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest steel rod manufacturers in China.

- Highest accurate dimensions: Our chrome plated CK45 hydraulic piston rod is manufactured with high dimension accurate, tolerance can be ISO f7, f8 or g6, according to client’s requirements. Which ensures the precision of the hydraulic cylinders or the machines.

- Higher yield strength: our chrome plated bar is with standard yield strength of min. 517 Mpa (75 ksi), and we can also supply chrome plated rod with yield strength of 10000 ksi and 15000 ksi up on customers’ requests.

- Reliable Packing: All the chrome plated bars will be oiled by the anti-rust oil before delivery. And to protect the outer surface of the chroming of CK45 chrome rods, we will use cardboard (paper tube) to pack each bar, and then pack with seaworthy package such as wooden cases or rope wraps.

- Excellent Quality Control: Our factory has a QC team of more than 10 persons. All the chrome rods will be inspected before packing. The inspections including: Chemical Analysis Test, Tensile Test, Dimension Inspection, Roughness Testing, Chrome plated thickness test and other tests according to standards and client’s requests.

- Our well-established quality management system ensures that every aspect of the production process that affects product quality is tightly controlled and monitored. This results in consistently high-quality products.