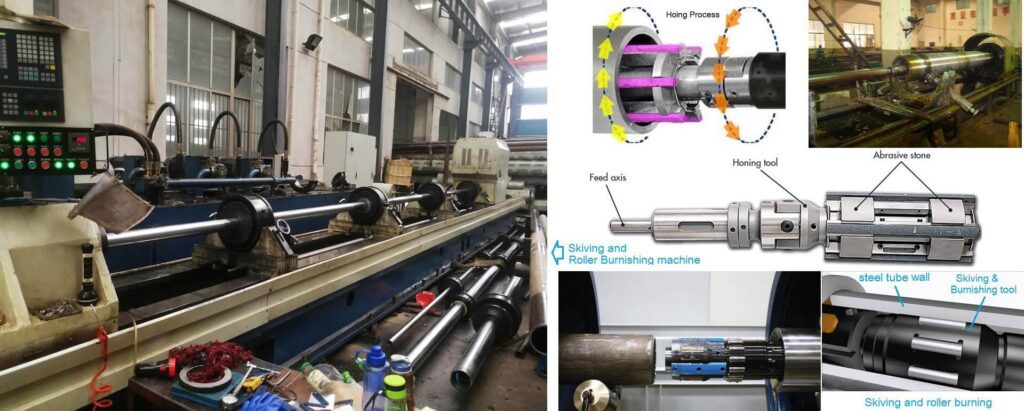

Honing process and Skiving & Roller burnishing (SRB) process are the two main types of processes for manufacturing hydraulic cylinder tube.

Tube Honing Process

Our factory utilizes the honing process to create smooth surface finishes on the inside diameter of honed tubes, while maintaining precise tolerances. This process involves using abrasive stones and paper to grind away surface imperfections that result from the cold drawing process, achieving the desired dimensional tolerances and surface finish. Cutting fluids are typically employed to facilitate easy cutting action and to remove the cut material from the bore. While producing honed tube, our factory uses the honing process to make smooth surface finishes of inside diameters; and to maintain exact tolerances on inside diameters.

Here below is a video which shows the cylinder tube honing operation.

Honing is a low velocity abrading process that differs from grinding. It generates less pressure and heat, so the surface, precision, and size of the finished product are not affected by heat stress. Precision cylinder tubes have excellent surface integrity and finish, high accuracy in inner diameter tolerances, and overall dimensions and geometry control that cannot be achieved with faster cutting speeds.

Tube ID Skiving and Roller Burnishing (SRB)

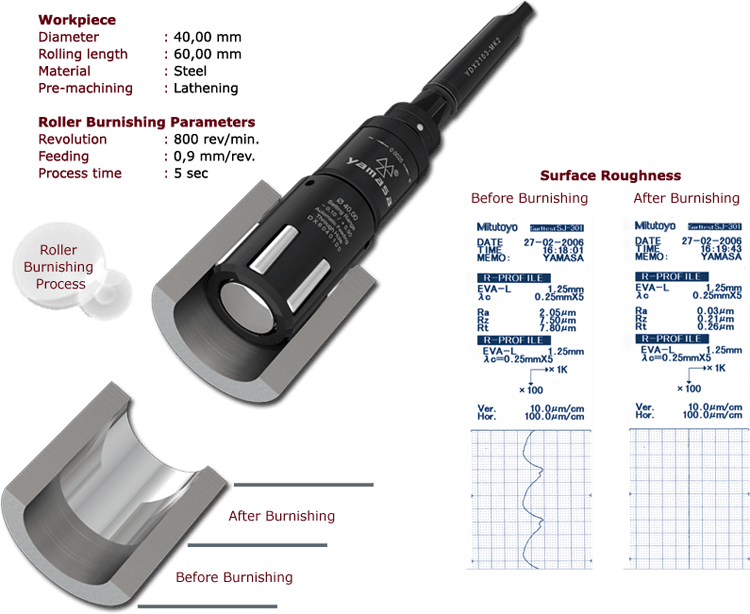

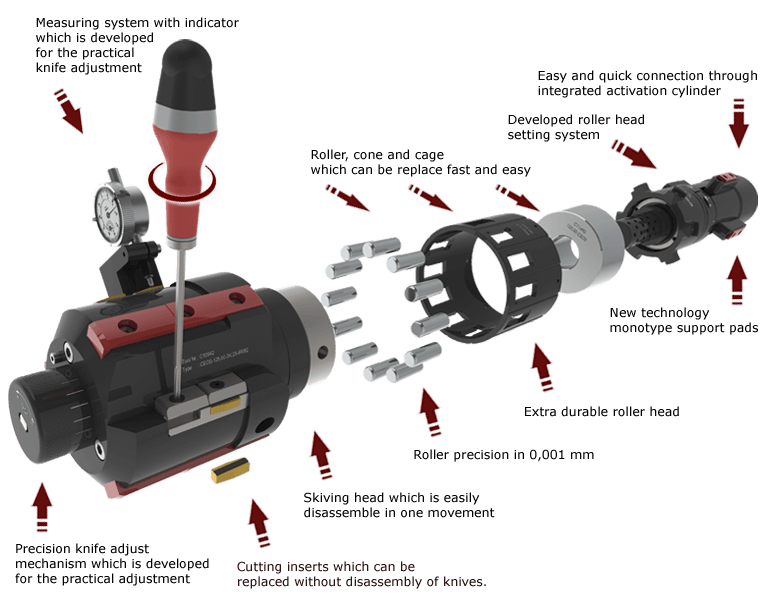

The skived & roller burnishing process is a single pass operation that uses a cutting tool on the forward stroke, to machine to size, and uses roller bearings on the reverse stroke, to burnish the inside surface.

Here below video is an introduction of hydraulic cylinder tube skiving and burnishing.

Skiving and roller burnishing process is faster than honing process; and typically generates more precise tolerances and better inside surface finish control than honing.

Here below is the features of honed tubes by Skiving and roller burnishing process.

Inside Diameter Range: 60-500 mm

Length of SRB tube: Up to 14 meters

Surface Roughness: Max Ra 0.4 microns.

Inside Diameter Tolerance: ISO – H7, H8, H9 on request.

Here below picture describes the main advantages of the skiving and burnishing process for manufacturing cylinder tubes.