Chrome plated OD tube also known as chrome plated hollow bar, it is a kind of very important material for various industries. Chrome plated OD tube is broadly used to produce hydraulic cylinder and penumatic cylinders with honed tubing and some other cylinder parts. Besides this, chrome plated hollow bar can be produced to Linear shaft for different machines. Normally chrome plated od tube is made of cold drawn seamless tubes with certain heat treatment condition. Here in this article, we briefly introduce the manufacturing process of chrome plated hollow bar.

Step 1. Purchase qualified raw material- seamless cold drawn tubes

The raw material for chrome plated tube are seamless cold drawn steel tubes. Usually the chrome plated tube manufacturer will buy the steel tube from the tube manufacturers. Some chrome plated hollow rod supplier its self is a seamless steel tube manufacturer.

There are many different steel grades of the steel tubes to make different chrome plated hollow rods, including SAE 1020, CK45, ST52 /E355 / ST52.3, 42CrMo, SAE4140, and so on.

After get the raw material, the factory need to inspect the raw material quality to make sure the raw material without any defects, which will lead the defects on the finished product.

Step 2. Heat treat the steel tubes according to customers’ requirements

Heat treatment is very important to chrome plated tubes, with heat treatment, the mechanical properties will be greatly increased, for the chrome plated hollow rods, the heat treatment type is usually stress relief heat treatment.

Step 3. Cutting the raw material hollow bar into lengths

If the customer requires the chrome plated od tubes with fixed length, the factory needs to calculate the length of the raw material and cut it to length and control the tolerance on length +/-2mm.

Step 4. Straightening the hollow rods

Step 5. Peeling on the steel hollow bar

To roughly remove the scales and other Surface Defects by peeling.

Step 6. Straightenning the steel tubes again

Step 7. Grinding the seamless steel tubes

Grinding the seamless steel tubes to the dimensions close to the finished dimensions.

Step 8. Straightening the ground hollow rods

Step 9. The second grinding process for the hollow rods

Step 10. Polishing on outer diameter surface

Polish on the outer diameter of the steel hollow bar to make the hollow bar to the required dimensions and the the surface roughness of Ra 0.2μm to 0.4μm, to get the steel hollow bar prepared for chrome plating.

Step 11. Chrome plating

Hard chrome plating the steel hollow bar to a certain chrome plated thickness, such as min. 20 microns, 25 microns, … 50 microns. After chrome plating, the steel hollow bar now can be called chrome plated hollow bar or chrome plated hollow rod or chrome plated tube.

Step 12. Final polishing

Here is the finishing polishing on the chrome plated outer diameter of the chrome plated od tube, to make the outer diameter surface super smoothly, and the roughness can be as good as Ra 0.2 microns (10RA).

Step 13. Final inspection

Do final inspection of the chrome plated od tubes, the inspections including dimension, straightness, surface roughness, hardness, chemical composition, and mechanical propterties test and so on.

Step 14. Packing the finished chrome plated tubes.

The finished qualified chrome plated tubes need to be well packed to prevent from any damages during moving, loading, transportation and unloading. Normally the chrome plated od tubes are lightly oiled and packed with hard cardboard sleeves to protect the outer surface. After that, they will be put into wooden cases or packed in bundles for further transporation.

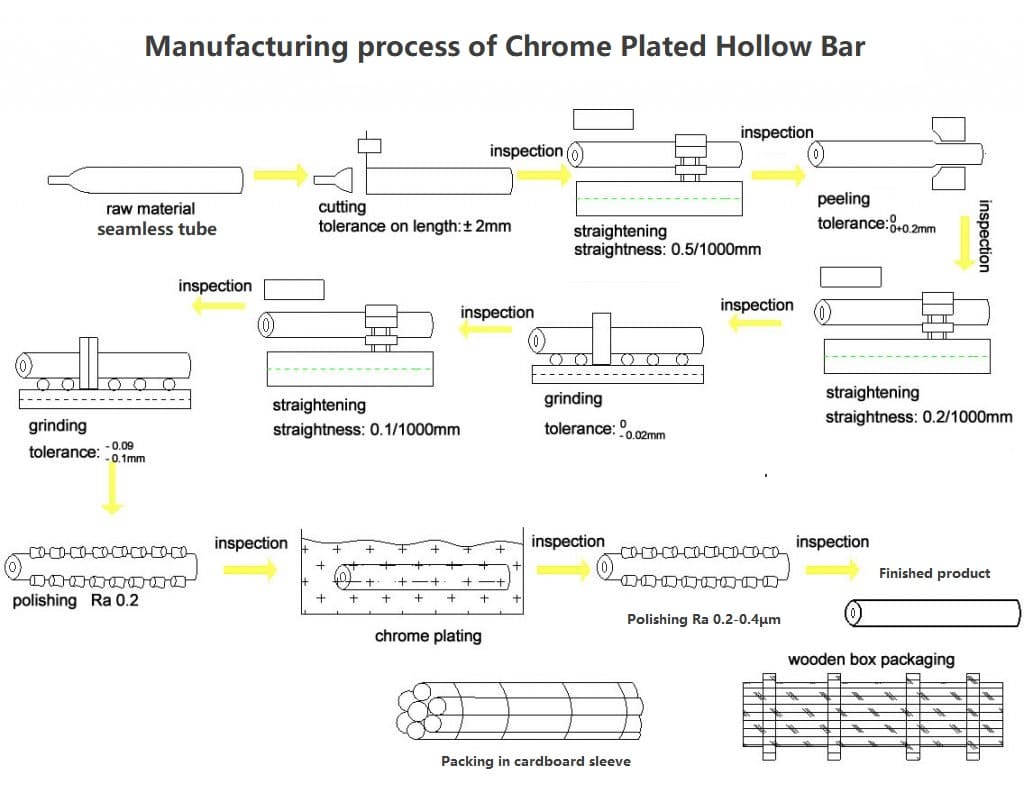

Here below is the manufacturing process flow chart of the chrome plated OD tubes.